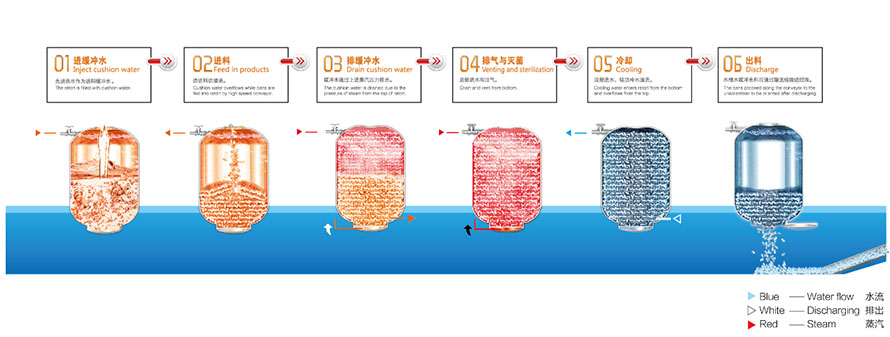

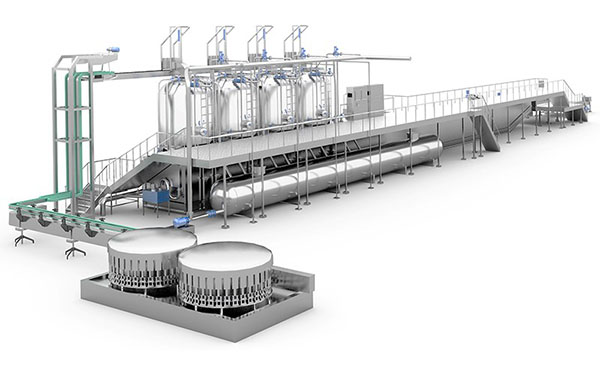

I-Vertical Crateless Retort System

Iphoyinti lokuqala le-Advantage, umphumela omuhle wokuvala inzalo, ukusatshalaliswa kokushisa okufanayo

Ubuchwepheshe bokungenisa umoya obuthuthukisiwe bamukelwa ukuze kuqinisekiswe ukuthi izinga lokushisa lilawulwa ku-±0.5℃ ngomphumela omuhle wokuvala inzalo.

Isikhathi esifushane sokulungiselela inqubo

Imikhiqizo ingafaka isicelo sokucutshungulwa kungakapheli umzuzu owodwa ngaphandle kokulayisha nokulinda ubhasikidi. Ukugcwalisa umkhiqizo oshisayo ukulahlekelwa ukushisa okuphansi, izinga lokushisa eliphezulu lokuqala, kunciphisa ukuthintana nomkhathi futhi kugcine izinga lokuqala lemikhiqizo.

Ukulawula ukunemba okuphezulu

Izinzwa zokushisa ezinembayo eziphezulu kanye nezinzwa zokucindezela ziyamukelwa ukuze zibone lonke izinga lokushisa nokulawula ingcindezi. Ukushintshashintsha kwezinga lokushisa esigabeni sokubamba kungalawulwa kokuthi plus noma susa 0.3 ℃.

I-Tractability

Idatha yokuvala inzalo (isikhathi, izinga lokushisa kanye nengcindezi) yeqoqo ngalinye lemikhiqizo nesikhathi ngasinye singabhekwa futhi silandelelwe nganoma yisiphi isikhathi.

Ukusebenza kahle kokonga amandla

> umjovo wesitimu kusuka phezulu, ukonga ukusetshenziswa kwesitimu

> Imfucumfucu ephansi evela kuma-bleeders, futhi alikho ikona elifile

> Ngenxa yokuthi amanzi ashisayo afakwa emkhunjini we-retort ngezinga lokushisa elifanayo nezinga lokushisa lokugcwalisa umkhiqizo (80-90 ℃), ngakho-ke umehluko wezinga lokushisa uyancishiswa, ngaleyo ndlela isikhathi sokushisa siyancishiswa.

Isibonisi sesithombe esinamandla

Isimo esisebenzayo sesistimu siboniswa ngamandla nge-HMI, ukuze opharetha acace mayelana nokugeleza kwenqubo.

Ukulungiswa okulula kwepharamitha

Ngokwezidingo ezihlukene zomkhiqizo, setha isikhathi, izinga lokushisa nengcindezi edingwa yinqubo, futhi usebenzise ngokuqondile idatha ehambisanayo yokufaka yedijithali esikrinini esithintwayo.

Ukucushwa okuphezulu

Izingxenye eziyinhloko zezinto zohlelo, izesekeli zikhethwa uphawu oluhle kakhulu (njengama-valve, amaphampu amanzi, i-motor geared, ibhande le-conveyor chain, uhlelo lokuhlola olubonakalayo, uhlelo lokulawula i-hydraulic, uhlelo lokulawula ugesi, njll.) ukuqinisekisa ukusebenza okuzinzile kwesistimu, ukwandisa impilo yesevisi.

Iphephile futhi inokwethenjelwa

Yamukela i-valve yokuphepha ephindwe kabili kanye nokulawula kokuzwa kwengcindezi ephindwe kabili, isakhiwo esime mpo, umnyango utholakala phezulu nangaphansi, susa ingozi efihliwe yokuphepha;

> Isistimu ye-alamu, isimo esingavamile sizovezwa esikrinini esithintwayo ngesikhathi ngokwaziswa komsindo;

> Iresiphi ivikelwe nge-password yamazinga amaningi ukuze kuqedwe amathuba okuhlukumeza.

> Yonke inqubo yokuvikela ingcindezi ingagwema ngempumelelo ukuwohloka kwamaphakheji omkhiqizo.

> Ngemva kokuthi isistimu isibuyiselwe ngemva kokuhluleka kwamandla, uhlelo lungabuyisela ngokuzenzakalelayo kuhulumeni ngaphambi kokuhluleka kwamandla.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur